Main Issue : Lack of soil data during growing season lowers yields and profits, and harms the environment.

Farmers don’t have real-time visibility into soil conditions as they’re working their fields. Without that visibility, farmers often over-or under-fertilize, harming profits and/or the environment.

Traditional soil samples and lab techniques take days to weeks to get results back, are expensive to obtain, and as a result, problems manifest in the plant before results are returned.

Solution:Teralytics

Get the most detailed soil quality data available, via a single probe with 26 sensors reporting soil moisture, salinity, and NPK at three different depths, as well as aeration, respiration, air temperature, light, and humidity.

No wires. Nothing to catch or snag. Easy to install and built to stand up to the wear and tear of your farm.

Key Features:

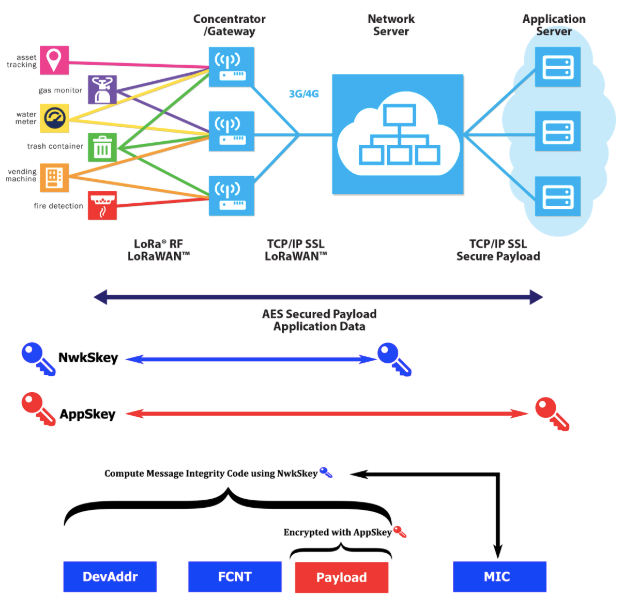

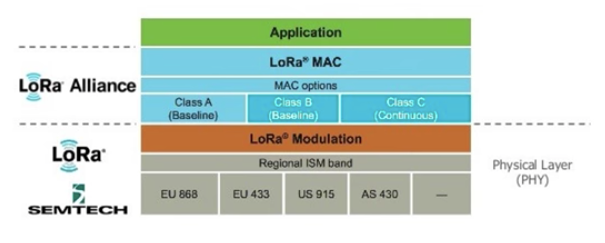

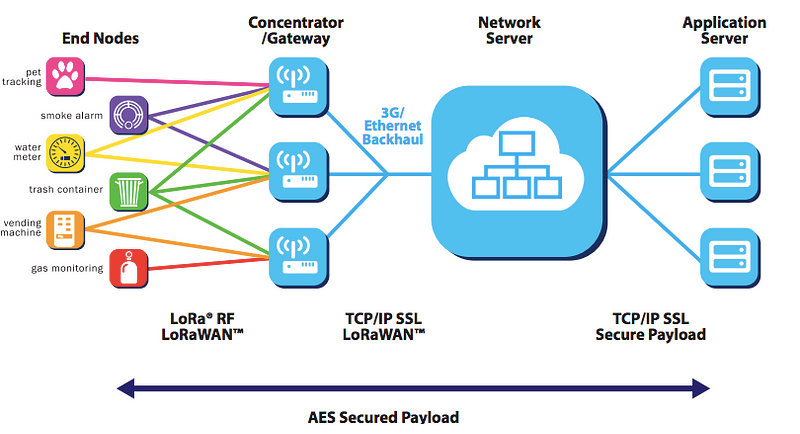

1. These probes collect data from your soils and send wirelessly via LoRaWAN, a long-distance network that transmits sensor data up to 10 miles away.

2. Wireless LoRaWAN gateways aggregate all probe data and send it to the cloud in a secure, continuous, live stream.

3. In cloud, we run analytics on your data based on soil conditions compiled by governments, universities, and the unique criteria from your farm.

4. Report back to you with real-time and predictive insights using readable charts - and you use the insight on your farm.

5.Send Sensor data to Teralytic Cloud via Cellular, WiFi, or Ethernet

Measure Soil electrical conductivity, moisture, pH, Nitrates, Phosphates, Potassium, and temperature at 3 different depths. Sample every 15 minutes

- Microclimate (Surface) :Air Temperature, Humidity, Light

- Soil Sensors : Soil Moisture, Salinity, Soil Temperature, pH, Nitrate, Potassium, Phosphorus

- Gas Sensors 18in / 6in Depths: Aeration (O2), Respiration (CO2)

Sensor Arrays Available for 3 Depths

6, 18 and 36 inches / 15, 45, and 90 cm give a stratified view of soils

Analytics:

Terascore is best-in-class metric that analyzes hundreds of data points from your farm and industry statistics to summarize what you need to know about your soil health.

Terascore is crop- and soil-type specific, so it is customized based on the unique profile of your farm.

If you prefer a more detailed breakdown - thye have that too.

Easily track how inputs affect your soil conditions and view historic averages reported for each sensor, at each depth.

Pricing :

As per website, they are sold out of Teralytic probes for Spring 2019 shipment–all new pre-orders will receive shipments in Fall 2019.

Teralytic SAAS-Based Business Model

•Soil Sensors as a Service: Teralytic charges up front per sensor plus a yearly subscription

•SaaS-based model includes sensors, networking, software and analytics

•Crop-based pricing: Crop type determines sensor density between 5–75 acres, which determines price

•Streamlined Onboarding and Ordering: Online tool during onboarding helps with sensor placement and pricing

For more information reach: https://teralytic.com/index.html

This article Teralytic || LoRAWAN Based Smart Farming is first time published on IoTVigyan , for any query or suggestion, feel free to reach on iotvigyan@gmail.com.

Reference : Internet